When it comes to selecting tiles for residential or commercial spaces, one of the most common questions is: Is this really porcelain, or just a ceramic tile with a fancy name? The differences between porcelain and regular ceramic tiles go beyond just appearance — they affect water resistance, durability, weight, and even installation methods. In this comprehensive guide, we’ll explore practical methods to distinguish porcelain tiles from standard ceramics, with hands-on techniques and professional insights. Whether you’re a builder, architect, or smart buyer, this guide will help you identify porcelain tiles with confidence and avoid costly mistakes.

What Is Porcelain Tile and How Is It Made?

The term porcelain originates from the Latin word referring to fine Chinese pottery — a nod to its ancient roots in China. While its conceptual birth was in the East, the evolution of porcelain tiles into industrial production actually began in Germany, where advanced manufacturing techniques shaped what we now know as porcelain tiles.

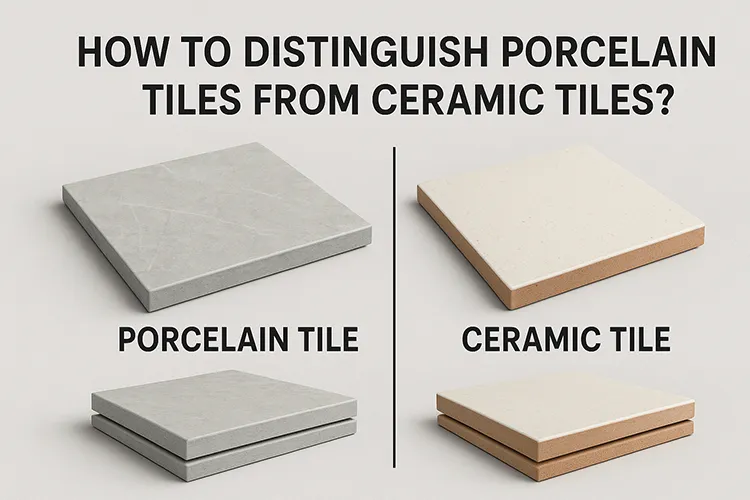

At a glance, porcelain tiles may seem similar to regular ceramic tiles, but there are two crucial differences that define them both structurally and functionally. First, the base material used: regular ceramic tiles are typically made with red clay, whereas porcelain tiles use a purer, white clay that’s rich in kaolin — a mineral known for its strength and whiteness. Second, firing temperature: porcelain tiles are fired at temperatures around 300°C higher than ordinary ceramic tiles. This high-temperature firing results in a denser tile body and dramatically lower water absorption — a key method to distinguish porcelain tiles from ceramic ones.

Suggested Article: Exporting Porcelain Tiles from Iran

Due to their advanced physical characteristics, porcelain tiles have gained significant popularity among builders and architects in recent years. With the growing construction demand, many tile factories across the country have shifted their production focus toward porcelain tiles. However, like all building materials, porcelain has both advantages and disadvantages — understanding them helps determine where and how to use them best.

Key Advantages of Porcelain Tiles

- Exceptional Bending and Load Resistance

Thanks to their dense body and high-quality raw materials, porcelain tiles boast excellent strength. In fact, under equal thickness, they can handle three times the pressure of natural stone. This makes them a go-to choice for high-traffic commercial spaces or heavy-use flooring applications.

- Superior Scratch and Wear Resistance

One of the most noticeable benefits when trying to identify porcelain tiles is their impressive resistance to abrasion. The glaze, formed through a high-temperature process and unique material blend, stands strong against sharp and abrasive tools — a clear advantage over standard ceramic tiles.

Suggested Article: Ceramic tile export from Iran

- Strong Resistance to Acids

While all ceramic-based tiles offer some resistance to acidic substances, porcelain tiles take it a step further. Their tighter structure and improved composition allow them to perform even better in harsh chemical environments, such as industrial kitchens or laboratories.

- Low Water Absorption and Freeze Resistance

Perhaps the most distinguishing feature of porcelain tiles is their near-zero water absorption, often below 0.5%. This quality not only makes them suitable for wet environments but also provides outstanding resistance against freezing and thawing cycles, which is essential for outdoor applications in colder regions.

Suggested Article: Exporting Porcelain floor tiles from Iran

Drawbacks of Porcelain Tiles You Should Know

While porcelain tiles offer a long list of benefits, no material is without its downsides. Understanding the limitations of porcelain tiles is just as important as recognizing their strengths, especially when deciding where and how to use them.

- Heavier Load on Building Structures

Because of their high density — and in some cases, increased thickness — porcelain tiles can be 20–30% heavier than standard ceramic tiles. This adds significantly to the dead load of a building. For this reason, it’s wise to limit the use of porcelain tiles to areas where their advanced properties are truly required, rather than using them by default.

Suggested Article: Exporting tiles to Europe from Iran

- Challenging Cutting and Drilling Process

One of the clear signs when learning how to identify porcelain tiles is their resistance to cutting. The same strength that makes porcelain tiles durable also makes them difficult to work with. Conventional cutting tools often fail; specialized equipment, such as diamond blades, is necessary to achieve clean cuts or drill holes without damaging the tile.

- Incompatibility with Regular Cement Mortar

Due to their extremely low water absorption, porcelain tiles do not bond well with traditional cement mortar. They require specialized adhesives designed for low-porosity surfaces. These adhesives tend to be more expensive, and installation may involve extra surface preparation. All of this contributes to a higher overall installation cost compared to ceramic tiles.

Suggested Article: Exporting tiles from Iran to GCC countries

- Higher Price Point

In terms of pricing, porcelain tiles vs ceramic tiles can differ significantly. Porcelain tiles typically cost 30% to 70% more than standard ceramic tiles. This price difference is due to higher-quality raw materials and more intensive manufacturing processes, as previously discussed.

Suggested Article: Exporting porcelain wall tiles from Iran

Common Applications of Porcelain Tiles

Thanks to their superior physical properties, porcelain tiles are ideal for high-performance applications in both residential and commercial environments. Here are some of the most popular areas where porcelain tiles are used:

- Building façades

- Parking garages and driveways

- High-traffic zones like hallways and stairwells

- Penthouses and rooftop gardens (roof gardens)

- Industrial floors in factories and production units

- Large retail spaces and hypermarkets

- Hotels and hospitality centers

- Hospitals and medical facilities

Suggested Article: Exporting Glazed Ceramic Tiles from Iran

Methods to Distinguish Porcelain Tiles from Regular Ceramic Tiles

Because of the close visual similarity — especially between white-body ceramic tiles and porcelain tiles — buyers and contractors often find themselves unsure whether a product is truly porcelain. If you’re wondering how to identify porcelain tiles, you’re not alone. In this section, we’ll walk you through some reliable, practical ways to distinguish porcelain tiles from standard ceramic ones, even without lab equipment.

-

Check the Packaging Label

The easiest and most immediate method to distinguish porcelain tiles is by inspecting the box. According to international and local standards, manufacturers are only allowed to label their product as “porcelain” if the tile has a water absorption rate of less than 0.5%. In practice, especially in countries like Iran, tiles with water absorption between 0.5% to 3% may still be marketed as porcelain, though true porcelain generally stays under the 0.5% mark. So always read the fine print on the packaging — it’s the first clue.

Suggested Article: Best floor tiles from Iran

-

Review the Laboratory Test Report

Every ceramic or porcelain tile manufactured should have a corresponding lab report detailing its physical and chemical properties. When in doubt, ask the seller to provide this sheet. Look for the term “Water Absorption” — if the value listed is under 0.5% (or even slightly under 1%), it likely qualifies as porcelain. Values between 1% to 3% indicate white-body ceramic, while anything above that is typical red-body ceramic tile. This is one of the most definitive porcelain tile identification methods.

-

Examine the Tile Body Color

Color alone isn’t a foolproof method, but it offers quick insight. Porcelain tiles typically have a white or light gray body due to the refined white clay used in production. In contrast, traditional ceramic tiles often have a reddish body. However, don’t assume all white-body tiles are porcelain — many non-porcelain ceramics also use white clay. The inverse, though, is generally true: red-body tiles are never porcelain.

Suggested Article: Exporting tiles to African markets from Iran

-

Compare the Tile Weight

Porcelain tiles are denser, which makes them noticeably heavier than standard ceramic tiles. For example, a 10mm thick regular ceramic tile may weigh around 22 kg per square meter, while porcelain tiles of the same thickness weigh closer to 27–30 kg/m². While this isn’t an exact science, it’s a useful rule of thumb when comparing two samples side-by-side.

-

Test Its Strength and Durability

Porcelain tiles are known for their physical toughness. One way to get a quick feel for this is to conduct a drop or load test (if you’re able). Drop a tile from waist height or apply pressure gradually — porcelain typically holds up better and resists cracking or chipping. This mechanical resistance is one of the reasons why porcelain is favored in high-traffic and commercial environments.

Suggested Article: Export floor tiles from Iran

-

Water Absorption Test (DIY-Friendly)

If you’re still unsure, try this simple test at home:

Lay the tile face-down and pour a small amount of water (about half a cup) onto the back of it. Let it sit for an hour. If the water remains on the surface without being absorbed, the tile is very likely porcelain. If the water slowly disappears or is fully absorbed into the body, it’s most likely a ceramic tile.

This method is especially handy for homeowners or small contractors who don’t have access to lab data.

By using these methods to distinguish porcelain tiles, you can shop with confidence and avoid confusion, especially when suppliers may label products ambiguously. Whether you’re a professional builder or a DIY homeowner, being able to tell the difference between porcelain tiles vs ceramic tiles can save you money, time, and a lot of future maintenance hassle.

Suggested Article: Exporting bathroom tiles from Iran

Final Thoughts: Choosing the Right Tile for the Right Purpose

Understanding the difference between porcelain and ceramic tiles is not just a technical exercise — it’s a crucial step in making the right investment for your space. Whether you’re renovating a home, outfitting a commercial property, or specifying materials for a large construction project, selecting the proper tile can directly impact both the aesthetics and long-term durability of your surface.

If your priority is resistance to water, foot traffic, chemicals, or extreme temperatures, porcelain tiles are often the superior choice. But with that performance comes a higher price, heavier weight, and stricter installation requirements. On the other hand, if budget-friendliness, easier handling, and moderate durability are your key concerns, high-quality ceramic tiles might serve your needs just as well.

Suggested Article: Exporting slab tiles from Iran

Practical Advice for Buyers:

- Don’t rely solely on color or glaze. Red-body vs. white-body isn’t enough to determine whether a tile is porcelain. Always check the packaging or lab report for water absorption data.

- Ask for documentation. A legitimate supplier should be able to provide lab test sheets or certifications, especially for large orders or commercial projects.

- When in doubt, test it out. DIY methods like water absorption tests or side-by-side weight comparison can go a long way when you’re working without technical tools.

- Match the material to the location. Don’t overspend on porcelain where it’s not needed — and never use standard ceramic in high-moisture, high-traffic, or freeze-prone zones.

- Installation matters. Porcelain tiles need proper adhesives and sometimes substrate preparation. Skimping on installation quality can nullify all their advantages.

Suggested Article: Export ceramic wall tiles from Iran

Conclusion

Now that you know the methods to distinguish porcelain tiles from regular ceramic tiles, you’re better equipped to make informed choices — whether you’re buying for a project, specifying for a design, or just learning to spot the difference. While manufacturers and retailers may blur the lines, the science and tests behind each tile don’t lie.

Your floors, walls, or facades deserve materials that match both your vision and the demands of the space. By learning how to identify porcelain tiles, you take control of both performance and budget, and that’s what smart building is all about.